APL Specification 5L/ISO 3183

Table 4 --Chemical composition for PSL 1 pipe with t ≤ 25,0 mm (0.984 in)

Steel grade

(Steel name) |

Mass fraction, based upon heat and product analyses a

% |

C

max.b |

Mn

max.b |

P

|

S

max. |

V

max. |

Nb

max. |

Ti

max. |

min. |

max. |

| Seamless pipe |

| L175 or A25 |

0,21 |

0,60 |

- |

0,030 |

0,030 |

- |

- |

- |

| L175P or A25P |

0,21 |

0,60 |

0,045 |

0,080 |

0,030 |

- |

- |

- |

| L210 or A |

0,22 |

0,90 |

- |

0,030 |

0,030 |

- |

- |

- |

| L245 or B |

0,28 |

1,20 |

- |

0,030 |

0,030 |

c,d |

c,d |

d |

| L290 or X42 |

0,28 |

1,30 |

- |

0,030 |

0,030 |

d |

d |

d |

| L320 or X46 |

0,28 |

1,40 |

- |

0,030 |

0,030 |

d |

d |

d |

| L360 or X52 |

0,28 |

1,40 |

- |

0,030 |

0,030 |

d |

d |

d |

| L390 or X56 |

0,28 |

1,40 |

- |

0,030 |

0,030 |

d |

d |

d |

| L415 or X60 |

0,28e |

1,40e |

- |

0,030 |

0,030 |

f |

f |

f |

| L450 or X65 |

0,28e |

1,40e |

- |

0,030 |

0,030 |

f |

f |

f |

| L485 or X70 |

0,28e |

1,40e |

- |

0,030 |

0,030 |

f |

f |

f |

| Welded pipe |

| L175 or A25 |

0,21 |

0,60 |

- |

0,030 |

0,030 |

- |

- |

- |

| L175P or A25P |

0,21 |

0,60 |

0,045 |

0,080 |

0,030 |

- |

- |

- |

| L210 or A |

0,22 |

0,90 |

- |

0,030 |

0,030 |

- |

- |

- |

| L245 or B |

0,26 |

1,20 |

- |

0,030 |

0,030 |

c,d |

c,d |

d |

| L290 or X42 |

0,26 |

1,30 |

- |

0,030 |

0,030 |

d |

d |

d |

| L320 or X46 |

0,26 |

1,40 |

- |

0,030 |

0,030 |

d |

d |

d |

| L360 or X52 |

0,26 |

1,40 |

- |

0,030 |

0,030 |

d |

d |

d |

| L390 or X56 |

0,26 |

1,40 |

- |

0,030 |

0,030 |

d |

d |

d |

| L415 or X60 |

0,26e |

1,40e |

- |

0,030 |

0,030 |

f |

f |

f |

| L450 or X65 |

0,26e |

1,45e |

- |

0,030 |

0,030 |

f |

f |

f |

| L485 or X70 |

0,26e |

1,65e |

- |

0,030 |

0,030 |

f |

f |

f |

a 0,50 % maximum for copper; 0,50 % maximum fo nickel; 0,50 % maximum for chromium; and 0,15 % maximum for molybdenum.

For grades up to and including L360/X52, Cu, Cr and Ni shall not be added intentionally.

b For each reduction of 0,01 % below the specified maximum concentration for carbon, an increase of 0,05 % above the specified maximum concentration for manganese is permissible, up to a maximum of 1,65 % for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1,75 % for grades >L360 or X52, but <L485 or X70; and up to a maximum of 2,00 % for grade L485 or X70.

c Unless otherwise agreed, the sum of the niobium and vanadium contents shall be ≤ 0,06 %.

d The sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

e Unless otherwise agreed.

f Unless otherwise agreed, the sum of the niobium, vanadium and titanium concentrations shall be ≤ 0,15 %.

|

Table 6

Requirements for the results of tensile tests for PSL 1 pipe

| Pipe Grade |

Pipe body of seamless and welded pipes |

Weld seam of EW,

SAW and COW pip |

Yield strengtha

R10,5

MPa(psi)

minimum

|

Tensile strengtha

Rm

MPa(psi)

minimum

|

Elongation

Af

%

minimum

|

Tensile strengthb

Rm

MPa(psi)

minimum |

| L175 or A25 |

175 (25 400) |

310 (45 000) |

c |

310 (45 000) |

| L175P or A25P |

175 (25 400) |

310 (45 000) |

c |

310 (45 000) |

| L210 or A |

210 (30 500) |

335 (48 600) |

c |

335 (48 600) |

L245R or BR

L245 or B |

245 (35 500) |

415 (60 200) |

c |

415 (60 200) |

L290R or X42R

L290 or X42 |

290 (42 100) |

415 (60 200) |

c |

415 (60 200) |

| L320 or X46 |

320 (46 400) |

435 (63 100) |

c |

435 (63 100) |

| L360 or X52 |

360 (52 200) |

460 (66 700) |

c |

460 (66 700) |

| L390 or X56 |

390 (56 600) |

490 (71 100) |

c |

490 (71 100) |

| L415 or X60 |

415 (60 200) |

520 (75 400) |

c |

520 (75 400) |

| L450 or X65 |

450 (65 300) |

535 (77 600) |

c |

535 (77 600) |

| L485 or X70 |

485 (70 300) |

570 (82 700) |

c |

570 (82 700) |

a For intermediate grades, the difference between the specified minimum tensile strength and the specified minimum yield strength for the pipe body shall be as given in the table for the next higher grade.

b For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

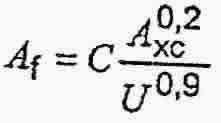

c The specified minimum elongation, Af expressed in percent and rounded to the nearest percent, shall be as determined using the following equation;

where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

Axc is the applicable tensile test piece cross-sectional area, expressed in square millimetres (square inches), as follows:

----- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2(0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

------ for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2);

----- for strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2(0.01 in2);

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

|

|